LEV TESTING SERVICES

Local Exhaust Ventilation (LEV) Testing Services

Our LEV Expertise and Services

Jasun Envirocare PLC has 40 years industry experience in: dust extraction, thorough LEV testing, inspection, repair and maintenance for all types and sizes of businesses across the UK and abroad.

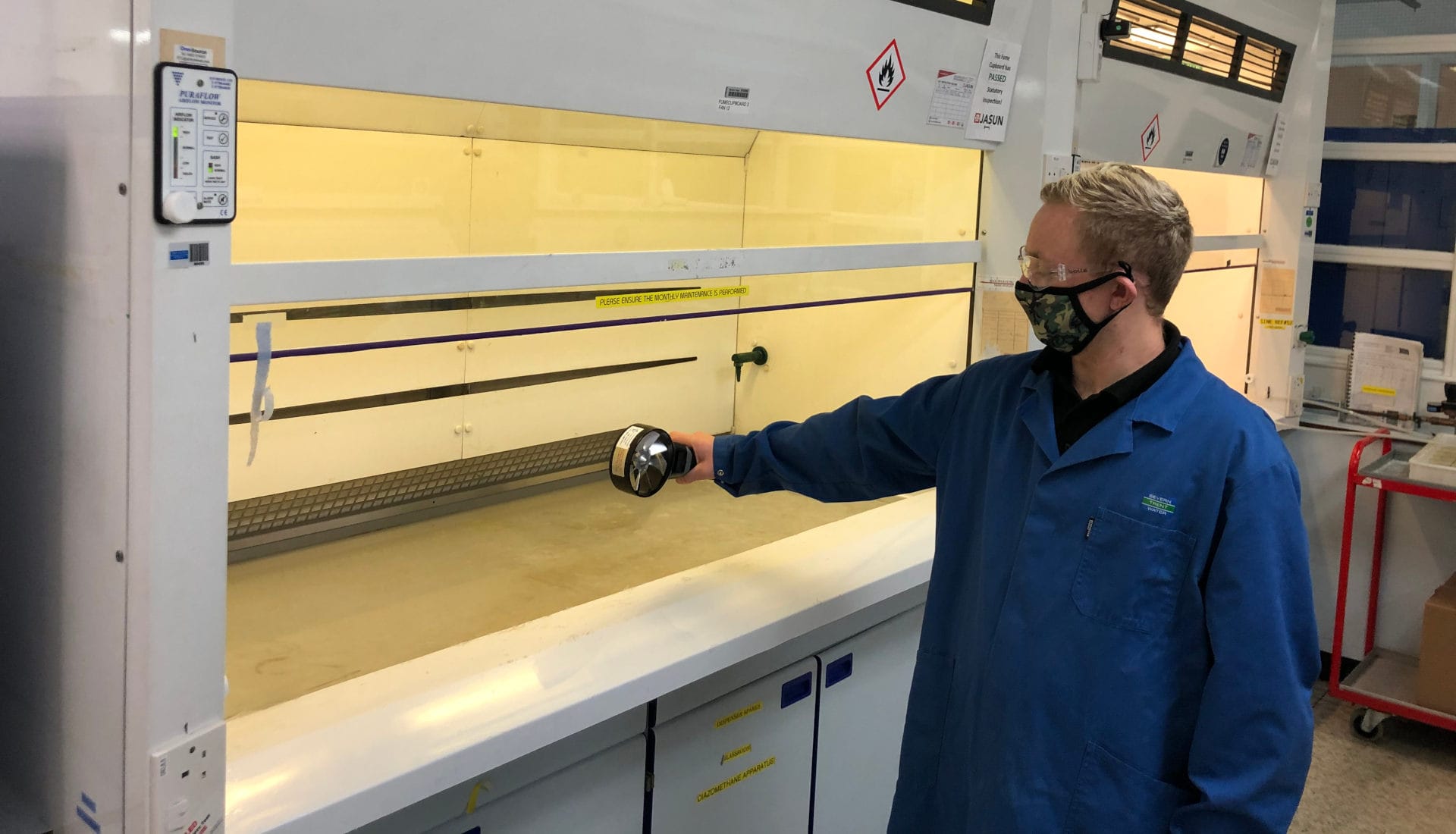

We undertake a thorough examination of LEV equipment including: hoods, filters and ducts, extraction servicing, personal air sampling and technical performance using state-of-the-art equipment and assess the effectiveness of the LEV system.

Where appropriate/necessary, we will make recommendations and can supply/order parts for any repair work. All our inspections and tests are fully in accordance with current Health and Safety Executive Control of Substances Hazardous to Health (COSHH) guidelines, which govern the LEV industry.

Our LEV engineers hold the BOHS (British Occupational Hygiene Society) P601 'Commissioning and Thorough Examination and Testing of Local Exhaust Ventilation Systems', which the HSE guidance (HSG258) refers to as one measure of competency in this area.

Our examinations are carried out with multiple methods of quantitative and qualitative testing, using a range of the best equipment and knowledge available. All our test equipment is fully calibrated for accuracy and tractability, with certification provided covering all aspects of the report.

We assess for industry standard practice in LEV system: design principles; initial installation; user active control measures and behaviours; users PPE (Personal Protective Equipment)... and the ventilation control of the substance/system as a whole.

Local exhaust ventilation or L.E.V. systems as they are more commonly known, are ventilation systems provided to control, capture and contain airborne contaminants such as dust, fumes and vapors in the workplace.

Properly designed LEV will:

• Collect the air that contains the contaminants, then ensure they are contained and taken away.

• Clean the air (if necessary) and get rid of the contaminants safely.

LEV systems must be examined and tested every 14 months under (HSE) Health & Safety Guidelines.

Click on the link below to download our Jasun Envirocare Local Exhaust Ventilation LEV Testing Technical Bulletin:

Local Exhaust Ventilation (LEV) Testing Services

What is Local Exhaust Ventilation (LEV)?

Each year thousands of workers in the UK develop illnesses such as lung disease, cancer and other complications as a result of exposure to airborne contaminates whilst at work. Any work that produces a dust, mist, fume, gas or vapour could be a substance hazardous to health and cause unnecessary risk to an employee’s health.

Employers are often unaware that their employees might be overexposed to potentially harmful airborne substances. This is contributed to by a number of factors, including inaccurate identification of the source of exposure, controls not being correctly used or the owner/manager being over optimistic about the effectiveness of their current controls.

A LEV system is an engineered solution specifically designed to capture and control any airborne substance before it can become inhalable and potentially harmful to the user. By means of appropriate extraction methods a LEV system provides control measures in the workplace preventing diseases and conditions occurring later in life.

Types of LEV equipment:

• Fume Cupboard

• Partial Enclosure Booth

• Extraction Canopy Hood

• On Tool Extraction

• Laminar Flow Cabinets

• Capture & Receptor Hoods

• Ducted and Recirculatory filtered systems

• Downdraught Benches

• Safety Cabinets

• Mobile and fixed LEV systems

LEV is a way of controlling and reducing the exposure of workers to airborne containments which could be hazardous to their health. For example, a manufacturing process may have localised extraction hoods connected with ductwork to a fan and filter which transports contaminated air away from the workers before discharging it into the atmosphere.

Typical industries and activities where the control of airborne hazardous substances may be needed:

• Saw mills and joinery

• Welding and sheet metal work

• Stone-masonry

• Manufacturing environments

• Factories

• Laboratories and chemical handling

• Schools, Colleges and Universities

• Garages

• Paint-spraying and powder coating

• Engineering

• Bakery and food manufacture

• Plating and metal treatment facilities

• CNC machining

• Grinding, finishing and polishing

• Fabric and material manufacture

Legal LEV Testing Requirement

It is a legal requirement, as set out in the Health and Safety at Work etc Act 1974, for any employer to maintain healthy working conditions for employees. The law states that any employer that uses LEV techniques in the workplace must have their equipment examined and tested every 14 months (under the current Control of Substances Hazardous to Health Regulations COSHH) to ensure it is working effectively and safely.

To keep legal, employers should ideally schedule examinations and testing every 12 months, to provide a two month period for any remedial work to be carried out.

Every employer who provides a LEV system must ensure: “...it is maintained in an efficient state, in efficient working order, in good repair and in a clean condition” - Regulation 9 -1 COSHH.

Good LEV service regimes and regular testing ensure that existing LEV systems continue to remove contaminants in the air before people breathe them in, delivering a safer workforce and cleaner environment.

Our LEV testing services include:

• A physical inspection of the system inclusive of a schematic diagram

• Providing a comprehensive LEV report, detailing performance rates of each system

• Issuing a Certificate of Compliance within COSHH requirements - should the LEV system pass HSE regulations

• A range of service packages

• Carrying out assessments of new ventilation systems for compliance with Building Regulations Approved Doc F.

Our reports clearly address and assess whether the LEV system complies with all current regulations and legislation:

• COSHH (Regulation 7)

• HSG258 (Controlling Airborne Contaminants at Work)

• Health and Safety at Work Act 1974

• Management of Health and Safety Work Regulations 1999

Call us now on: 01278 452 277

Order products online at: www.jfilters.com